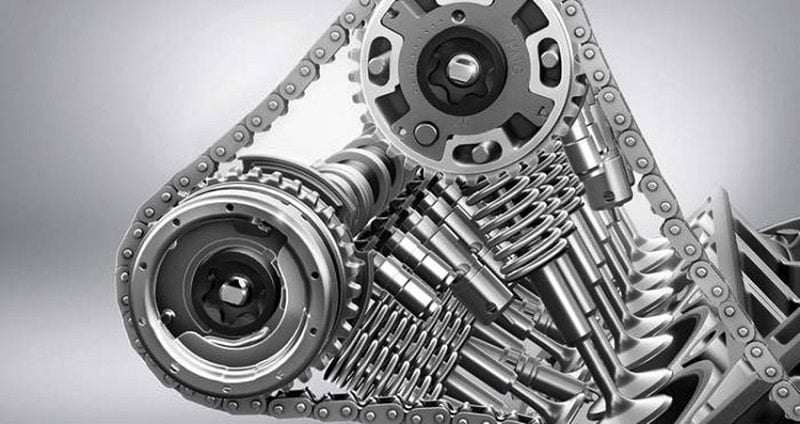

CVVT gear

Import CVVT gear

Camshaft Variable Valve Timing (CVVT), also known as variable valve timing, is a mechanical technology used in the engine valve system. CVVT allows you to control the opening and closing times of the valves in the engine and adjust them precisely. The main application of CVVT is to increase engine efficiency and improve its performance.

By changing the closing and opening times of the valves, the engine can provide the best fuel and air mixture in each speed and load range of the engine. This results in better engine performance at low and high speeds, load distribution between cylinders, and reduced fuel consumption. Also, CVVT can improve the engine’s output power for more acceleration and performance. In practice, the CVVT system is controlled by an actuator, engine accessories, or hydraulic systems.

CVVT system components

The Camshaft Variable Valve Timing (CVVT) system consists of several components. Here are some of the main components of CVVT:

Drive Mechanism: The drive mechanism of the CVVT system is responsible for transferring motion from the engine to the CVVT parts. This includes gears, rotors, chains, or hydraulic safeties that are affected by the engine’s force.

Sensors: Sensors in CVVT are used to measure various parameters. For example, sensors can measure engine speed, oil pressure, temperature, and valve positions. This information is sent to the CVVT control system and used in adjusting the timing of the valves opening and closing.

Oil Transfer: For the proper functioning of CVVT, oil is used as a working substance in the system. Oil is transferred to the system using an oil pump and is transferred to the rotors or hydraulic systems to control the movement of the valves.

Gears and Cogs: Gears and cogs in the CVVT system are used to transfer motion from the engine to the CVVT parts. These gears and cogs are mechanically placed in the engine architecture and help change the timing of the valves opening and closing.

Controller or Control Unit: The controller or control unit of CVVT is responsible for controlling the system’s operation. This includes microprocessors, electronic circuits, and related control systems. The controller receives information from the sensors and, depending on the engine’s operational conditions and specific settings, controls the timing of the valves opening and closing.

Hydraulic System (if present): In some hydraulic CVVT systems, there is a special system for controlling the flow of oil to the valves and moving parts of CVVT using a hydraulic pump. This hydraulic system helps change the timing of the valves opening and closing.

The components of CVVT may vary depending on the design and technology used in each system. However, these components are essential and play a significant role in controlling the timing of the valves opening and closing and adjusting the operation of CVVT.

How CVVT gear works

The Camshaft Variable Valve Timing (CVVT) system generally works by adjusting the timing of the valves opening and closing, controlling the flow of fuel and air in the cylinders. The operation of CVVT is as follows:

Type of CVVT:

Before examining the operation of CVVT, it’s important to identify the type being used. CVVT can be mechanical, hydraulic, or electronic. Each type of CVVT system has its own way of working, but the overall goal of adjusting the timing of the valves opening and closing is the same.

Valve System:

CVVT relies on components such as gears, cogs, compressors, and dampers in adjusting the timing of the valves opening and closing. These components are connected to the valve stem and control floats.

Timing Control:

CVVT uses a specific control system to adjust the timing of the valves opening and closing. This control system can be mechanical, hydraulic, or electronic and uses sensors, microprocessors, and controllers.

Timing Adjustment:

The timing of the valves opening and closing is adjusted by the CVVT system based on various factors such as engine speed, engine load, and engine temperature. By changing the timing of the valves opening and closing, CVVT adjusts the amount of fuel and air mixture and optimizes engine performance.

The Camshaft Variable Valve Timing (CVVT) technology has a wide range of applications in vehicles. Here are some of the main uses of CVVT:

- Improving Performance at Low Speed Ranges: One of the main uses of CVVT is to improve engine performance at low speeds. By adjusting the timing of the valves opening and closing, CVVT can provide the best fuel and air mixture at low speeds. This performance improvement includes increased engine torque and power, reduced noise and vibration, and improved engine responsiveness in idle mode.

- Improving Performance at High Speeds: CVVT is also of high importance at high speeds. With precise adjustment of the timing of the valves opening and closing, the power and efficiency of the engine can be improved at high speeds. This can help increase achievable speed, more acceleration power, and better performance in high-speed driving.

- Reducing Fuel Consumption: CVVT has a direct significant impact on reducing fuel consumption. By optimizing the timing of the valves opening and closing, the amount of fuel needed for each combustion cycle is reduced. This can significantly improve fuel delivery performance and reduce fuel consumption in various driving conditions, including city and highway driving.

- Improving Combustion Quality: CVVT can make a significant improvement in the quality of engine combustion. By changing the timing of the valves opening and closing, an improvement in the combustion cycle, pollutant emissions reduction, impurities reduction, and improved fuel distribution in the cylinders can be experienced. This improvement in combustion quality can have environmental benefits by improving engine performance and reducing pollutants.

- Increasing Engine Life: By using CVVT, drastic changes can be made in the engine valve system. These changes can result in an improvement in the performance and quality of the valves, reduced wear and tear, and increased useful life of the engine.

Variable Valve Timing (VVT) systems are used as a technology in internal combustion engines to precisely adjust the timing of the valves opening and closing. These adjustments improve engine efficiency, fuel consumption, reduce pollutants, and other engine performance features. Below are examples of types of variable valve timing systems:

- CVVT (Continuous Variable Valve Timing): This type of variable valve timing continuously adjusts the timing of the valves opening and closing. This technology has been developed by various companies under different names such as VVT-i (Toyota), VTEC (Honda), and MIVEC (Mitsubishi).

- VVT (Variable Valve Timing): This type also controls the change in timing of the valves opening and closing. Some companies use this term to name their technology, for example, BMW calls it “VANOS”.

- VVL (Variable Valve Lift): In this system, in addition to changing the valve timing, the height of the valves opening and closing also changes. This technology helps to control the air and fuel intake flow into the cylinders more precisely.

- Dual VVT-i/Dual VVT (Dual Variable Valve Timing): This type of system allows two pairs of valves (fuel valves and exhaust valves) to be adjusted independently, improving engine performance across a wider range of speeds.

- MultiAir: This technology has been developed by FCA (Fiat Chrysler Automobiles) and uses a hydraulic system to change the timing and opening and closing of the valves instead of using mechanical floats.

All these types of technologies have a common goal, that is, to improve engine efficiency and performance, increase fuel economy, and reduce environmental pollution. Each type has its own features, advantages, and disadvantages that depend on engine development and design.

The impact of the CVVT system on engine power and efficiency

The CVVT system has a significant impact on engine power and efficiency. Below, we explain in detail the impact of CVVT on engine power and efficiency:

Increasing engine power: CVVT allows the engine to produce more power at high speeds and under high load. By adjusting the timing of the opening and closing of the valves, CVVT can allow the engine to produce the optimal fuel-air mixture at maximum torque and power. This improvement in power can lead to increased achievable speed, better acceleration, and more output power.

Improving engine efficiency: CVVT improves the overall efficiency of the engine. By optimally adjusting the timing of the opening and closing of the valves, the engine can provide the best fuel-air mixture in each speed and load range. This improvement in efficiency can lead to reduced fuel consumption, reduced pollutant emissions, and increased combustion cycle efficiency.

Improving combustion quality: CVVT creates a significant improvement in engine combustion quality. By changing the timing of the opening and closing of the valves, improvements can be experienced in the combustion cycle, fuel distribution, reduction of impurities, and improvement of air and fuel distribution in the cylinders. This improvement in combustion quality leads to increased engine power and efficiency, reduced fuel consumption, and reduced pollutant emissions.

Improving vehicle acceleration: CVVT improves vehicle acceleration. By precisely adjusting the timing of the opening and closing of the valves, the engine can provide better responsiveness and more output power in acceleration modes. This improvement in acceleration can make the driving experience more enjoyable and improve the dynamic performance of the vehicle.

In general, CVVT improves engine power and efficiency by adjusting the timing of the opening and closing of the valves and improving combustion quality. This admirable use of CVVT in vehicles has led to a significant improvement in vehicle efficiency and performance.

The impact of the CVVT system on fuel consumption

The CVVT system has a significant impact on engine fuel consumption and can create a significant improvement in vehicle fuel consumption. Below, we explain in detail the impact of CVVT on fuel consumption:

Optimization of combustion timing: One of the main benefits of CVVT is the ability to optimize combustion timing. By precisely adjusting the timing of the opening and closing of the valves, CVVT enables the engine to provide the best fuel-air mixture in each speed and load range. This improvement results in the most optimal fuel consumption under all driving conditions.

Reduction of fuel waste: By optimizing combustion timing and fuel-air mixture, CVVT facilitates the reduction of fuel waste. By creating better and more complete combustion, fuel is burned more optimally in the engine and the least amount of fuel is wasted. This leads to reduced fuel consumption and increased fuel efficiency.

Improvement of combustion quality: CVVT has a direct impact on combustion quality. By changing the timing of the opening and closing of the valves, CVVT can create improvements in fuel distribution, reduction of impurities, and improvement of air and fuel distribution in the cylinders. This improvement in combustion quality leads to more optimal fuel consumption and reduced emissions.

Optimal adjustment of fuel amount: CVVT enables the engine to consume the most optimal amount of fuel in each driving state. By adjusting the timing of the opening and closing of the valves based on the engine’s needs at each moment, the amount of fuel consumed is minimized and optimized to provide the necessary power and performance.

In general, CVVT, by optimizing combustion timing, improving combustion quality, and optimally adjusting the amount of fuel, can create a significant improvement in vehicle fuel consumption. This admirable use of CVVT in vehicle engines helps reduce fuel consumption and reduce vehicle fuel costs.

Advantages and disadvantages of the CVVT system:

Advantages of the CVVT system:

- Improving engine performance: CVVT, by adjusting the timing of the opening and closing of the valves, can improve engine power and performance. This improvement includes increasing engine torque and power, improving acceleration and output power at high speeds, and improving performance at low speeds.

- Optimizing fuel consumption: One of the main advantages of CVVT is reducing fuel consumption. By optimally adjusting the timing of the opening and closing of the valves, CVVT reduces the amount of fuel consumed and increases fuel efficiency.

- Reducing pollutants: By improving combustion quality and optimal fuel distribution in the cylinders, CVVT helps reduce pollutants. This improvement can lead to reduced pollutant emissions and improved air and environmental quality.

- Increasing engine life: By optimally adjusting the timing of the opening and closing of the valves, CVVT can create an improvement in the quality and performance of the valves and reduce valve wear. This can generally increase the life of the engine.

Disadvantages of the CVVT system:

- Cost: Installing the CVVT system in engines is costly and may increase the price of the vehicle. Also, the need for maintenance and repairs related to CVVT can increase repair and maintenance costs.

- Complexity: The CVVT system is more complex than fixed valve systems and requires advanced technology and precise control. This may require more technical expertise and knowledge in engine maintenance and repairs.

- System complexity: The installation and adjustment of the CVVT system are complex and require technical skill and expertise. Also, a malfunction or defect in the CVVT system may affect the overall performance of the engine and require complex repairs.

- Reliability: Due to its complexity and advanced technology, some users may not have complete confidence in the performance and reliability of the CVVT system. In case of a malfunction or defect in the system, repair and reconstruction may be problematic.

Despite the mentioned advantages and disadvantages, CVVT is generally an effective technology that improves engine performance and efficiency. However, the final decision to use CVVT should be made considering the needs and advancements of automotive manufacturing and the preferences of manufacturers.

Signs of CVVT malfunction

The signs of a CVVT system malfunction may include the following:

- Decreased engine power: One of the signs of CVVT malfunction can be a decrease in engine power and performance. If the CVVT system does not work properly, the timing of the opening and closing of the valves is set improperly, which can lead to a decrease in engine power and torque.

- Increased fuel consumption: Another sign of CVVT malfunction is increased fuel consumption. The timing of the opening and closing of the valves is set incorrectly, which can lead to incomplete combustion of fuel and increased fuel consumption.

- Unnatural noise: In case of CVVT malfunction, you may hear unnatural and rough noises in the engine. These noises can include ragged, hissing, or divergent sounds that indicate a CVVT system malfunction.

- Incorrect engine combustion: In case of CVVT system malfunction, the engine may combust incorrectly and possibly enter combustion at incorrect timing. This can lead to increased backfiring, vibrations, and instability in engine performance.

- Decreased engine life: The CVVT system helps adjust the timing of the opening and closing of the valves so that the engine operates in the best possible way. In case of CVVT malfunction and incorrect valve timing, faster wear may occur in engine parts and the useful life of the engine may decrease.

- Lighting of the error light: In some vehicles, CVVT malfunction may cause the engine error light (Check Engine) to turn on. In this case, the error detection device (OBD-II) can record and display error codes related to the CVVT system.

If you encounter any of the signs of CVVT malfunction, it is recommended to take your vehicle to an experienced mechanic and reputable engine expert for a complete diagnosis and necessary repairs. Repair and maintenance of the CVVT system may require technical expertise and access to special equipment.

Results of using the CVVT system in car engines

The use of the CVVT system in car engines can lead to the following positive results:

- Improving engine performance: One of the important results of using the CVVT system is improving engine performance. By adjusting the timing of the opening and closing of the valves during engine rotation, CVVT can improve engine power and torque. This performance improvement is particularly noticeable at high speeds and engine output.

- Optimizing fuel consumption: One of the important benefits of CVVT is improving fuel consumption. By adjusting the timing of the opening and closing of the valves based on engine conditions, CVVT minimizes fuel consumption and increases fuel efficiency. This can have a positive impact on reducing fuel costs and ensuring vehicle financial efficiency.

- Reducing pollutants: By improving combustion quality and optimizing fuel distribution in the cylinders, CVVT can help reduce pollutants and environmental pollution. Better valve performance and improved fuel and air mixture can lead to reduced pollutant emissions and improved air quality.

- Improving power delivery: The use of the CVVT system can improve engine power delivery. By adjusting the timing of the opening and closing of the valves, CVVT can provide a better distribution of air and fuel in the cylinders and consequently increase power and engine efficiency.

- Improving combustion quality: By optimizing the timing of the opening and closing of the valves, CVVT can create an improvement in combustion quality. This improvement includes reducing impurities, improving fuel and air distribution in the cylinders, and creating better and more complete combustion.

In general, the use of the CVVT system in car engines can bring about a significant improvement in performance, fuel consumption, and pollutant reduction.

For the import of various types of spare parts, including spare parts for domestic and foreign cars, contact Tata Trading Company. Our connection with various companies around the world enables us to provide you with the best and highest quality spare parts from different brands, bringing you a profitable and easy trade.